A plug weld is used to fasten two pieces of metal together using a welder. When joining the pieces, a hole is drilled into the top piece and it is laid over the bottom one. A weld is then made by running a bead inside of the drilled hole, thereby holding the two pieces together. When doing auto body repair, this type of weld is often used when replacing body panels. The finished result resembles a spot weld in that it is circular.

Plug and slot weld design For customers accessing the services from Great Britain (“GB”) MT SecureTrade Limited is licensed and regulated by the Gambling Commission plug and slot weld design and holds a plug and slot weld design Remote Casino Operating License number 39575. 2.3.3 Plug and Slot Welds. The effective area of a plug or slot weld shall be the nominal area of the hole or slot in the plane of the faying surface. 2.3.4 The effective weld size of a combination PJP groove weld and a fillet weld shall be the shortest dis-tance from the joint root to the weld face of the diagram-matic weld minus 3 mm 1/8 in. Welding Design Creating Welding Features Creating Welds Plug and Slot Welds About Slot Welds. About Slot Welds. A slot weld joins the surface of a piece of material to another piece through an elongated hole. The hole can be open at one end and can be partially or completely filled with weld material.

When joining two dissimilar thicknesses of metal, the plug weld is often the weld of choice. By welding the thin top piece to a thicker bottom piece, a strong weld can be produced. While this type of weld is occasionally used to connect two thick sheets of steel together, it is primarily a thin metal weld. When making one, welders need to be careful not to burn through the bottom piece of metal.

The weld is also used when welding a rod inside of a pipe. When the fit is such that the rod or bolt stud fits snugly inside of a hollow tube, a hole is drilled into the tube and a plug weld is used to secure the rod inside of it. Occasionally, this method is also used when welding thin exhaust pipes onto a vehicle. Once the exhaust sections are installed, the pipe is welded using this method to secure the system underneath the vehicle.

The calculation is intended for the geometrical design and strength control of statically loaded welded connections of machine structures manufactured from carbon steels. The program enables you to design over 50 of the most common types of welded connections stressed by various combinations of load.

The calculation deals with the following tasks

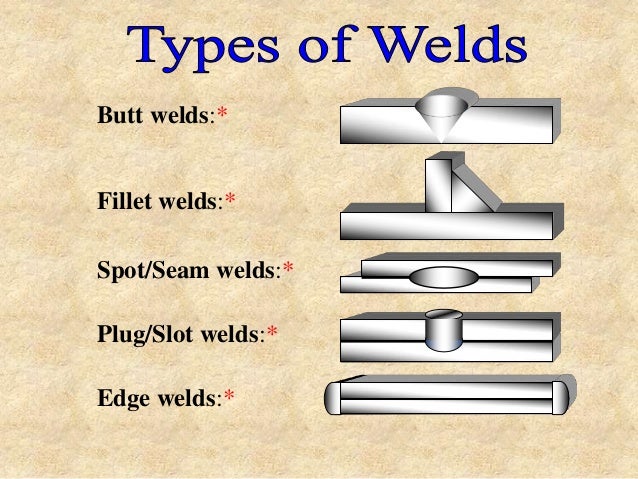

- Design of connections with butt welds.

- Design of connections with fillet welds.

- Design of connections with plug and slot welds.

- Design of connections with spot (resistance) welds.

- Strength control of designed connections.

- The program includes a table with approx. 700 carbon steels suitable for welding according to the material standards ANSI, EN, JIS, ISO, DIN, BS, NF, UNI, UNE, SIS, CSA, NBN, NP, NS, ON and CSN.

- The program also includes a dimensional table of steel sections S, ST, W, WT, C, L according to ASTM/AISI/AISC and T, I, U, L sections according to DIN/EN/ISO.

The calculation is based on data, procedures and algorithms from specialized literature and standards AWS, AISC, ANSI, EN, ISO, DIN and others.

List of standards: prEN 1993-1-8, EN 10024, EN 10034, EN 10055, EN 10056, EN 10279, DS 952, DIN 15018, DIN 18800, DIN 1024, DIN 1025, DIN 1026, DIN 1028, DIN 1029, CSN 050120

* MITCalc Welded Connections download link provides trial version of the software.

MITCalc Bolted Connections is designed for a geometrical design and strength check of a prestressed bolt connection, loaded by static or cyclic loading resp. , acting both in the axis of the bolt and in the plane of the connected parts.

The application is designed for calculations of straight, maximum three times static indefinite beams with constant axis-symmetrical profiles.

MITCalc is the mechanical, industrial and technical calculations package. This professionally multi-language prepared package includes solutions for gearings, belt and chain drives, bearings, springs, beams, shafts, bolt joints and many others.

The calculation is designed for geometrical designs and complex examinations of shafts.

MITCalc Buckling is designed to calculate the optimum cross-section and perform strength check of slender struts strained for buckling

MITCalc Profiles solves area characteristics of common profiles and mass characteristics of solids created by drawing or rotation of the profile.

What Is A Slot Weld

No comments yet. Be the first to comment.

Plug And Slot Weld Definition

Submit a review using your Facebook ID